Labor to Install Vinyl Siding: Costs, Time, Skills, and Safety Measures

Exploring the realm of labor involved in installing vinyl siding, this comprehensive guide delves into the various aspects that impact the process. From costs to time requirements, necessary skills, and safety measures, this article provides a holistic view of what it takes to ensure a successful vinyl siding installation.

Cost of Labor for Installing Vinyl Siding

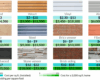

Installing vinyl siding typically involves labor costs that can vary depending on various factors. The average labor cost for vinyl siding installation ranges from $4 to $7 per square foot. This cost usually includes the removal of old siding, preparation of the surface, installation of the vinyl siding panels, and cleanup.

Factors Influencing Labor Costs

- The size of the project: Larger projects may require more labor hours, impacting the overall cost.

- Location: Labor costs can vary based on the region due to differences in labor rates and availability of contractors.

- Complexity of the installation: Intricate designs or difficult-to-reach areas may require more labor and expertise, increasing the cost.

Professional Installation vs. DIY

- Professional Installation: Hiring a professional contractor ensures proper installation, potentially reducing the risk of errors or damage. However, it comes at a higher cost due to labor fees.

- DIY Installation: Opting for a DIY installation can lower labor costs, but it requires adequate skills and tools. Mistakes in DIY installations can lead to additional expenses for repairs.

Negotiating Labor Costs

- Get Multiple Quotes: Obtain quotes from different contractors to compare labor costs and services offered.

- Ask for Discounts: Inquire about any ongoing promotions or discounts that contractors may offer for vinyl siding installation.

- Flexible Scheduling: Contractors may be willing to adjust labor costs if you are flexible with the installation timeline.

Time Required for Installing Vinyl Siding

Installing vinyl siding on a home is a labor-intensive process that requires careful planning and execution. The time it takes to complete the installation can vary based on several factors, including the size of the home, the complexity of the design, and the experience level of the installation crew.

Average Time for Installation

On average, it can take anywhere from 1 to 3 weeks to install vinyl siding on a typical home. This timeframe includes preparation work, such as removing old siding or prepping the exterior, as well as the actual installation of the vinyl siding panels.

Factors Affecting Installation Time

Size of the Home

Larger homes will naturally take longer to side compared to smaller homes.

Design Complexity

Intricate designs or patterns may require more time to install properly.

Weather Conditions

Adverse weather, such as rain or extreme heat, can slow down the installation process.

Crew Experience

A skilled and experienced crew will work more efficiently than a less experienced team.

Step-by-Step Breakdown of Tasks

- Preparation: This involves removing old siding, repairing any damaged areas, and ensuring the surface is clean and ready for installation.

- Measuring and Cutting: Each vinyl siding panel needs to be accurately measured and cut to fit the specific dimensions of the home.

- Installation: Starting from the bottom, the panels are installed one by one, ensuring they are level and securely attached.

- Trim Work: Trimming around windows, doors, and corners adds a finishing touch to the installation.

- Clean-Up: Once the siding is installed, the work area should be cleaned up and any debris removed.

Tips for Expediting the Installation Process

Proper Planning

Ensure all materials and tools are ready before starting the installation.

Team Coordination

Effective communication and coordination among the installation crew can speed up the process.

Work in Sections

Breaking down the installation into manageable sections can make the process more efficient.

Quality Control

Regularly check the installation to address any issues promptly and avoid delays.

Skill and Expertise Needed for Vinyl Siding Installation

Installing vinyl siding requires a certain level of skill and expertise to ensure a successful outcome. Whether you are a DIY enthusiast or a professional contractor, understanding the necessary skills and expertise is crucial for a smooth installation process.

Skills Required for Vinyl Siding Installation

- Knowledge of basic carpentry: Understanding how to measure, cut, and install siding pieces accurately is essential for a seamless finish.

- Ability to work with power tools: Utilizing tools such as a circular saw, level, and hammer correctly is important for efficiency and precision.

- Attention to detail: Being meticulous in aligning and securing siding panels will result in a visually appealing and durable installation.

- Problem-solving skills: Addressing challenges like uneven walls or obstacles requires adaptability and creative solutions.

Expertise Needed for Vinyl Siding Installation

- Experience in siding installation: Prior knowledge of working with siding materials and techniques is beneficial for a professional finish.

- Understanding of building codes: Complying with local regulations and standards ensures a safe and code-compliant installation.

- Ability to work at heights: Comfort and safety while working on ladders or scaffolding are essential for successful siding installation.

Challenges and Tips for Vinyl Siding Installation

- Challenge: Warping or buckling of siding panels due to improper installation.

Tip: Ensure panels are properly aligned, nailed securely, and have sufficient room for expansion and contraction.

- Challenge: Water infiltration behind the siding causing damage to the structure.

Tip: Install a moisture barrier and flashing to prevent water intrusion and protect the building envelope.

- Challenge: Inconsistent seams or gaps between siding panels affecting the appearance.

Tip: Use a level and spacer blocks to maintain uniform spacing and create seamless transitions between panels.

Improving Labor Efficiency and Workmanship

- Plan and organize: Measure and cut all materials beforehand to streamline the installation process.

- Work in teams: Collaborate with others to divide tasks and increase productivity on larger projects.

- Invest in quality tools: Using high-quality equipment can improve efficiency and accuracy during installation.

Safety Measures for Labor During Vinyl Siding Installation

Installing vinyl siding can be a rewarding project, but it’s crucial to prioritize safety at all times. Here are some essential safety measures that laborers should follow to ensure a safe working environment during vinyl siding installation.

Common Safety Hazards and Mitigation

- Wearing appropriate protective gear, such as gloves, safety goggles, and hard hats, can help prevent injuries from sharp tools or falling debris.

- Ensuring ladders are stable and securely placed to avoid falls from heights while working on siding installation.

- Checking for electrical wires or hazards behind the siding before starting the installation process to prevent potential accidents.

- Properly handling and storing tools to avoid tripping hazards and injuries during the project.

- Being cautious of weather conditions, such as wind or rain, that can impact the safety of the installation process and take necessary precautions.

Best Practices for Laborers

- Communicating effectively with team members to coordinate tasks and ensure everyone is aware of safety protocols during the installation.

- Taking regular breaks to prevent fatigue and maintain focus on the task at hand, reducing the risk of accidents.

- Following manufacturer’s guidelines and instructions for proper installation techniques to avoid mistakes that could lead to injuries.

- Inspecting the work area regularly for any potential hazards and addressing them promptly to maintain a safe working environment.

- Seeking training and certification in vinyl siding installation to enhance skills and knowledge, improving safety practices on the job.

Final Summary

In conclusion, labor to install vinyl siding requires meticulous planning, skilled expertise, and adherence to safety protocols. By understanding the costs, time commitments, required skills, and safety measures, individuals can navigate the process effectively and achieve a durable and visually appealing exterior for their homes.

FAQ Compilation

What factors can influence labor costs for vinyl siding installation?

Factors such as the size of the project, location, complexity of the design, and contractor experience can impact labor costs for vinyl siding installation.

How can one negotiate labor costs with contractors for vinyl siding installation?

To negotiate labor costs, consider obtaining multiple quotes, discussing the scope of work in detail, and highlighting any competitive offers you may have received from other contractors.

What are some common safety hazards associated with vinyl siding installation?

Common safety hazards include working at heights, handling sharp tools, exposure to chemicals, and lifting heavy materials. Proper training and adherence to safety protocols can help mitigate these risks.